High Quality Laser and Plastic Welding Services

Plastic can be used in different kinds of applications and they can also be turned into different kinds of materials. They are commonly found in a lot of products and equipment in our times today because of the flexible properties that they have. There are also plastics that are resistant to a lot of chemicals that is why they are also used as an effective storage device. If you are in need of plastic products, we should know that there are businesses that are specialized in manufacturing these kinds of materials. Read this helpful article to know how you can choose the best laser plastic welding services.

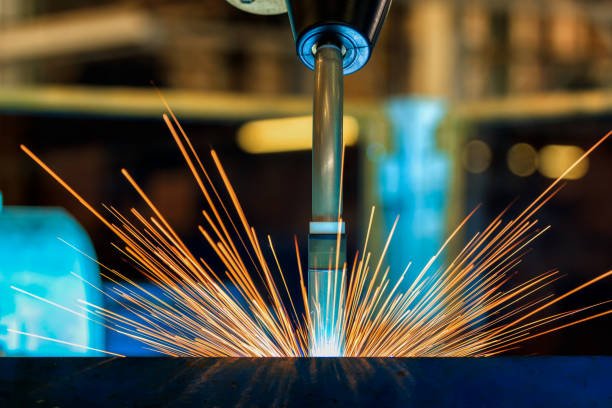

They are able to offer us with services involving the development of certain products that are made out of polymers as well as in customizing their features so that we can get the results that we want. Handling plastic can be quite a delicate process as they can be molded with the use of heat but it also requires a lot of precision. There are now companies that are using laser equipment in order for them to be able to do some welding or have some marking done on plastics.

It can be quite a delicate process that would require the right equipment and expertise for the job. The transmission of heating that can be done on plastics are able to easily mold its surface or the material that it has. But we should also know that we need to have the proper knowledge of its components so that the results would be smooth. Plastic can easily burn if there are foreign materials that are mixed with it and if the heat is too strong. Its structure may also be affected if the temperature would spread all over its surface.

We should do some research so that we can get information on businesses that offers a total solution on plastic processes. They are able to provide us with a lot of excellence in their manufacturing systems as well as in the developments of the products that we are going to need. We are able to learn more about laser welding from them as well as on the different kinds of applications that they can be used from. Their plastic solutions would involve decorating, finishing, inkjet printing, bonding and a lot more. We would surely be able to find a lot of options and applications on the products that we are developing with their help.

We can have our packaging to be manufactured by them as well as other kinds of equipment that would require some marking on the materials that are going to be used. We should get in touch with these businesses so that we can get to know more about the services that they offer. We should know how much their products and services would cost us and we should also have some knowledge on the quality that they have. Looking for an established manufacturer is important as they are the ones that gives a lot of importance to the satisfaction of their customers.